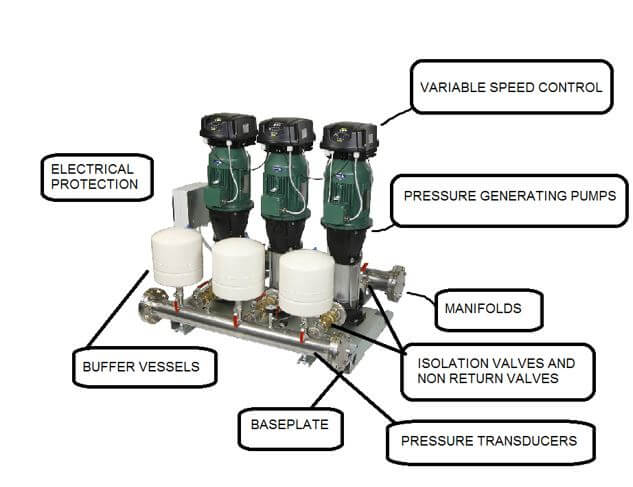

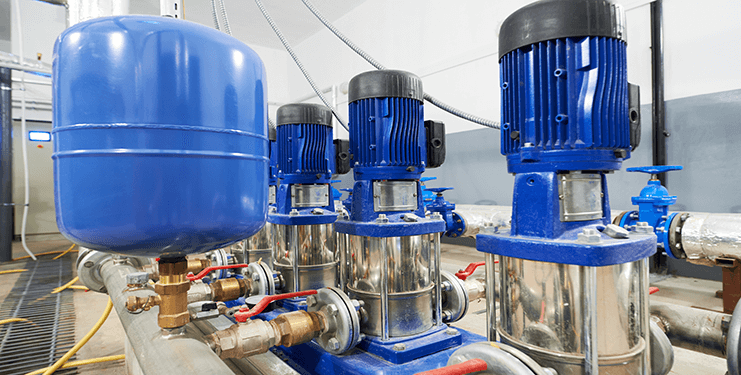

Booster pumping systems or booster sets are a proven and effective solution for increasing water pressure, particularly in larger buildings.

Booster pumps are commonly used in environments such as apartments, hotels, schools, leisure centres and other buildings where it is essential that all outlets have access to adequate water pressure.

Unfortunately, booster pumps can experience problems; especially when they are not properly maintained. Booster pumps underperformance or complete failure can be extremely disruptive and often results in some or all building occupants having no access to water or experiencing low pressure.

In environments such as apartments, a booster pump failure could mean that residents do not have sufficient pressure to carry out essential daily tasks such as having a shower, flushing the toilet or using their taps.

To prevent this, our latest blog post takes a look at 7 problems with booster pumps and how you can fix them. The most common problems with booster pumps include:

- Pump won’t start

- High running noise

- Leaking from pump

- Contamination

- Low water pressure

- High operating costs

- Pressure too high

Pump Won’t Start

A booster pump that won’t start means that water will not be available to any outlet fed from the pumps.

There are several reasons why a booster pump doesn’t start including a lack of power, water in the break tank, tripping, sensor failure, problems with the control panel and motor failure.

Firstly if there is a power cut then the pumps won’t run and there will be no water delivered. When the electricity is reinstated the pumps might need to be reset to work, if in doubt please call our professional engineers for further assistance.

If the ball valve has failed in the break tank and the pumps are fitted with low level protection then the pumps won’t start. Check the tank has water.

If these have been checked the other potential causes can be difficult to fix the issue without sufficient knowledge and expertise of booster pumps. Therefore, it is recommended to arrange a full inspection from a pump engineer.

High Running Noise

A high running noise from your booster pump is not only a sign of potential problems, but can also be frustrating for building users as they may be woken or otherwise disturbed by the higher operating noise.

There are several reasons why a booster pump can make excessive noise including high demand, incorrect positioning, worn or old components and excessive vibration from the pump or pipework within the building.

Along with regular maintenance, it’s possible to prevent noise from your pump by ensuring it can meet demand and using vibration isolators such as vibration mats, bases, and springs.

To find out more about this problem, take a look at our blog post on best practice for controlling noise in booster pumping systems.

Leaking from Pump

Leaking from your booster pump reduces its effectiveness and can result in more serious problems if not addressed. Leaks can be caused by issues such as broken valves, worn or cracked seals and the water pressure being too high.

To determine the cause of the leak, we recommend carrying out an inspection of the pump and its components. If you are unable to identify the issue, a full service should be arranged with a pump engineer.

If you are responsible for the maintenance of a booster set, take a look at our free booster pump maintenance inspection checklist which covers the key components of the pump that should be inspected regularly.

Contamination

Contamination is a serious issue in any pumping system, but even more so with a booster set where end users are likely to be using and drinking the water it’s distributing.

Contamination can be caused by inadequate cleaning of the pump or failing to manage the maintenance requirements of the cold water storage tank.

If there is contamination within the pump, it should be switched off immediately and a full inspection should be arranged with an engineer who can test, clean and disinfect the cold water tank.

Low Water Pressure

The primary purpose of booster pumps is to increase the pressure of water, so it’s an immediate cause for concern if low water pressure is experienced.

A drop in pressure could be caused by high demand, the age and suitability of the pump, a faulty sensor, valve failure or a leak.

We recommend carrying out a visual inspection on the unit before arranging an inspection by an engineer who can assess whether a repair is required or whether the pump is no longer up to the job and needs replacing.

To find out more about what causes low water pressure and how you can improve it, take a look at our blog post on how to improve water pressure.

High Operating Costs

If you have noticed an increase in operating costs, it may not be down to increasing energy prices alone. As pumps age, they become less efficient; particularly if they are not being professionally maintained.

With the new features offered by modern pumps, upgrading can offer potentially thousands in cost savings whilst providing a better experience for residents and reducing your carbon footprint.

If your bills are increasing, we recommend arranging a pump energy check. This check gives you an accurate view of current pump performance and can calculate whether any cost savings could be made by upgrading the unit.

Pressure too High

When a pumps pressure is too high, it puts unnecessary strain on the pump and pipework without offering any real benefit to the users of the building.

One of the most common reasons for the pressure being too high is the pressure relief valve (PRV) which controls pressure being set too high or being stuck open.

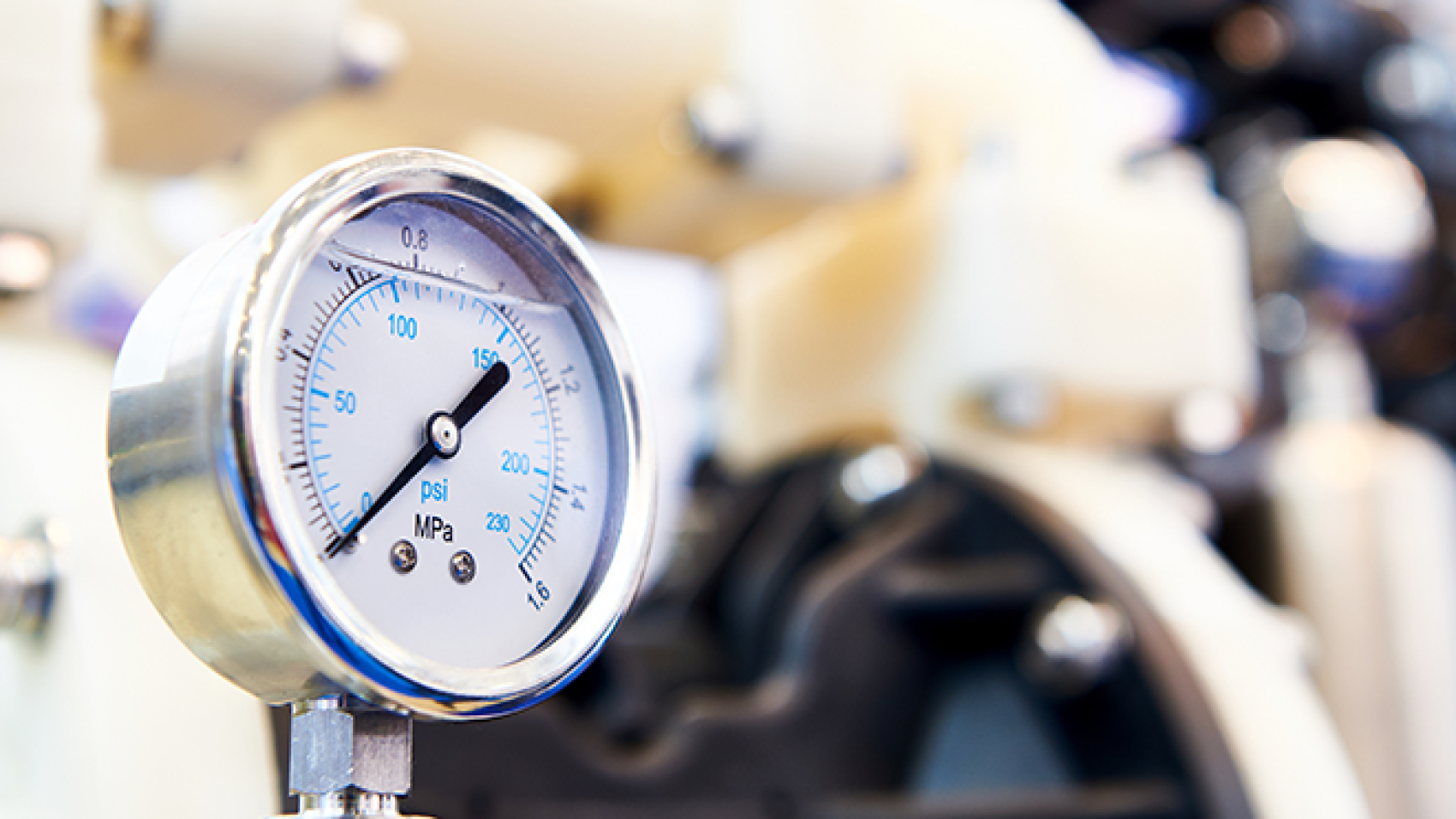

If your pressure is running too high, we recommend checking the pressure gauge and manually reducing the pressure if required. If the PRV does not close or the pressure will not decrease, organise an inspection from an engineer.

Professional Booster Set Repairs and Maintenance

If you are experiencing issues with your booster pumps, we can help. Our engineers have years of experience in the design, installation and commissioning, repair and ongoing maintenance of booster pumps from leading manufacturers.

For more information, call us today on 0117 954 8030 or fill out a contact form and we will get back to you.